Size: 1.44'' - 55''

Structure: G+G, G+F, G+F+F, P+G

Touch Performance: Pool of Water, Water + Gloves + Stylus, Thick Gloves, High Frequency Electromagnetic Interferences, etc

Customization Ability: Full range of Customization for Cover, Sensor, IC and Bonding, etc.

Materials: Glass(max support 10mm, Opti White Glass & Opti Float Glass, Thermally & Chemicaly Tempered), PMMA (max support 5mm)

Color: Gradient logo printing, Ceramic printing, Anti-UV light ink printing

Shape: 3D cover glass customization, CNC the holes, sliders, concave buttons, polishing treatment, etc.

polishing

polishing

CNC the holes

CNC the holes

sliders concave buttons

sliders concave buttons

3D cover glass customization

3D cover glass customization

Step glass design

Step glass design

Ceramic printing

Ceramic printing

Anti-UV light ink printing

Gradient logo printing

Gradient logo printing

Photoreal on cover glass

Photoreal on cover glass

Max to 5mm PMMA

Max to 5mm PMMA

Max to10mm Glass

Max to10mm Glass

With make Anti-Fingerprint coating on cover glass, it will be hard to leave fingerprint on screen and the water on glass would be drops, no spread over.

Water contact angle on screen will be >110゜

Applications: Handheld devices, Laboratory devices, etc

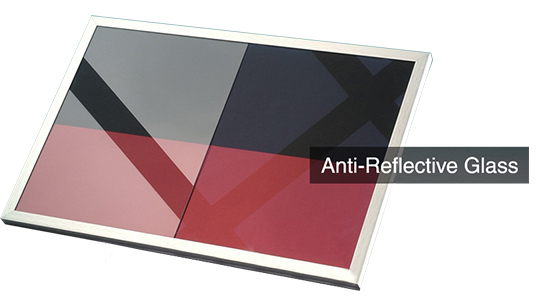

Cover lens transmittance: 94% ~ 99%

Cover lens reflection: 0.5% ~ 5%

20000 times friction under 2kg pressure with use 0# steel velvet.

Salt Foggy testing: Test 480H under 5% NaCl, 48℃.

Production process: Evaporation, Sputtering, Soaking

Applications: Sunlight Readable Solutions with improve the visual effect, etc

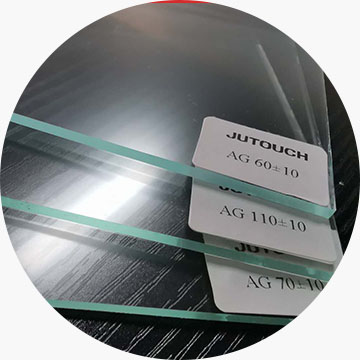

Customized values of Gloss are available in JuTouch.

Production process:

Chemical etching process (long service life, JuTouch mainly used)

Coating process (high gloss value consistency, high gloss value)

Spraying process (easy to fall off)

Selective Etching AG Glass (make Etching AG Treatment on screen but leave the camera area be no AG)

Application: Outdoor use devices with ask sunlight readable, Indoor use devices with ask anti-glare from lights, etc

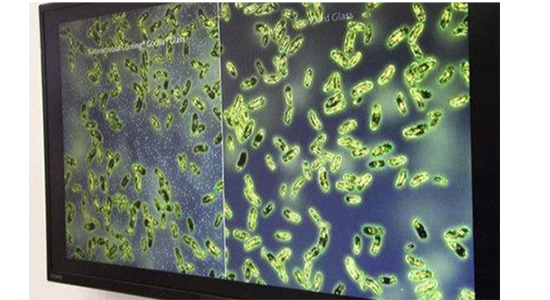

By adding nano-silver material into SiO2 for coating process, it helps to break the bacterial cell wall so as to destroy the bacteria. The coating film cured by high temperature improves the adhesion that can warrant the use for 10 years.

Min.size:25x25mm

Max. size:2000x1500mm / 100inch diagonal cover glass

| IC | Size Support | Interface | Waterproof | Gloves | Thickness of coverlens | Lifetime |

|---|---|---|---|---|---|---|

| ≤10.1” | IIC | A large pool of water | ≤5mm gloves | ≤8mm glass,≤4mm PMMA | >5 years |

| ≤43” | USB/UART/IIC | A large pool of water | ≤5mm gloves | ≤10mm glass,≤4mm PMMA | >5 years |

| ≤31.5'' | IIC/USB | A large pool of water | ≤5mm gloves | ≤5mm glass,≤3mm PMMA | >5 years |

| ≤84” | USB/UART/IIC | A large pool of water | ≤5mm gloves | ≤5mm glass,≤3mm PMMA | >5 years |

| ≤13.3” | IIC | Water foggy / Wet fingers | ≤3mm gloves | ≤3mm glass,≤2mm PMMA | >2 years |

Supporting wide variety of operating systems (Linux, Windows, IOS, and Android)